Cable assembly is an important component in most rapidly changing industries today. It ensures a very good connection for the data and energy transfer. From telecommunications to automotive, aerospace to industrial automation, cable assembly is an important part that makes the performance and reliability of entire systems. As there’s development in this industry base, the demand for quality cable assembly Indonesia has grown considerably.

The following reading will tackle the basic tips in selecting the right cable assembly in Indonesia; it helps ensure you make informative decisions according to your specific needs and the industry standards.

Understand Your Requirements and Specifications

Before choosing a cable assembly, it is critical to thoroughly understand your project’s requirements. Consider the following factors:

- Purpose: Identify whether the assembly is for power transmission, data communication, or a combination of both.

- Environment: Evaluate the operating conditions, such as temperature, humidity, and exposure to chemicals or mechanical stress.

- Electrical specifications: Define the voltage, current, and signal type that the cable assembly must handle.

Understanding these specifications will help you narrow down your options and ensure compatibility with your system.

Select the Appropriate Cable Type

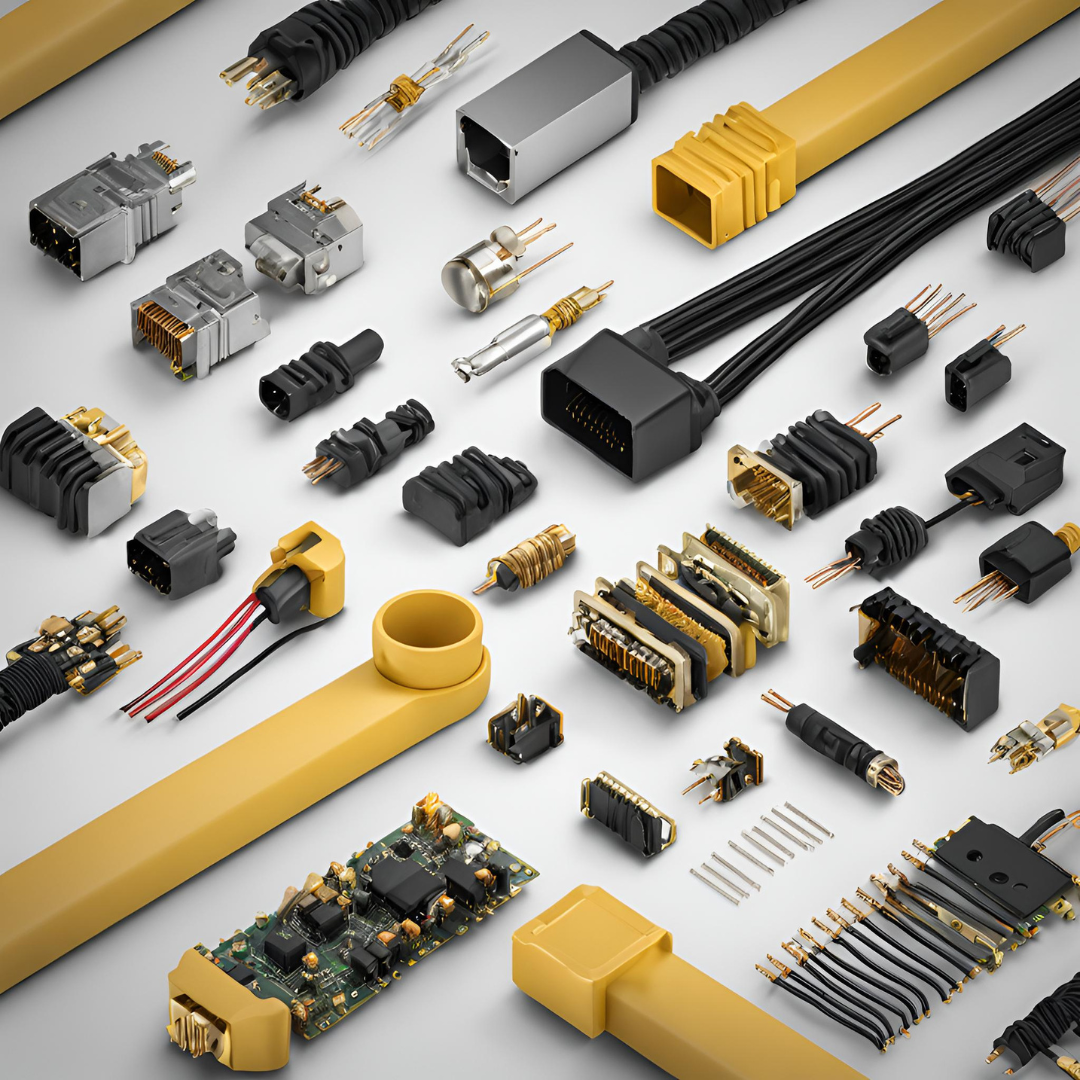

There are different types of cable assemblies, each designed for specific applications. Some common types include:

- Coaxial cables: Ideal for high-frequency signal transmission, often used in telecommunications and broadcasting.

- Fiber optic cables: Known for high-speed data transmission with minimal signal loss, suitable for long-distance communication.

- Power cables: Designed to carry electrical power in industrial and commercial settings.

- Custom assemblies: Tailored to unique specifications, providing flexibility for specialized projects.

Choose a cable type that meets your technical needs and aligns with your industry’s standards.

Prioritize Quality and Certifications

In Indonesia, the quality of cable assemblies can vary widely. To ensure reliability and safety, prioritize products that meet international standards and certifications, such as:

- ISO 9001: A certification indicating that the manufacturer follows stringent quality management systems.

- UL certification: Ensures that the cable assembly meets safety standards for electrical equipment.

- RoHS compliance: Indicates that the assembly is free from hazardous substances, making it environmentally friendly.

High-quality cable assemblies not only enhance performance but also reduce the risk of failures and maintenance costs.

Consider Customization Options

Off-the-shelf cable assemblies may not always meet the specific needs of your project. In such cases, opting for customized solutions can be beneficial. Many cable assembly providers in Indonesia offer customization services, allowing you to specify:

- Length and connectors: Customizing the length and type of connectors ensures a perfect fit for your application.

- Shielding and insulation: Enhanced shielding and insulation can improve signal integrity and protection in challenging environments.

- Labeling and color coding: This simplifies installation and maintenance, especially in complex systems.

Collaborate with a trusted manufacturer to design a solution tailored to your exact specifications.

Evaluate the Manufacturer’s Reputation and Expertise

Choosing a manufacturer of the cable assembly Indonesia is crucial to the success of your project. When evaluating potential suppliers in Indonesia, consider the following:

- Experience: Manufacturers with extensive industry experience are more likely to deliver high-quality products.

- Customer reviews and references: Seek feedback from previous clients to gauge the manufacturer’s reliability and service quality.

- Technical support: Ensure that the manufacturer provides technical support and after-sales services, which can be invaluable in resolving issues.

A reputable manufacturer will not only provide superior products but also offer valuable guidance throughout the selection process.

Assess Flexibility and Lead Times

In fast-paced industries, timely delivery of components is critical. Assess the manufacturer’s ability to accommodate your schedule and adapt to changing requirements. Consider factors such as:

- Lead times: Choose a supplier with a proven track record of meeting deadlines.

- Inventory management: Some manufacturers offer inventory management services, ensuring a consistent supply of cable assemblies.

- Scalability: Ensure that the supplier can scale production to meet future demand increases.

Flexibility in production and delivery can significantly impact your project’s timeline and success.

Evaluate Cost vs. Value

Cost is an important factor. However, it can’t be the sole focus. Instead, prioritize the overall value, which encompasses:

- Durability: A higher upfront investment in durable cable assemblies can reduce long-term maintenance costs.

- Performance: High-performance assemblies contribute to the efficiency and reliability of your system.

- Warranty and support: Manufacturers offering comprehensive warranties and support services provide added peace of mind.

Balancing cost and value ensure that you achieve optimal results without compromising quality.

Plan for Future Expansion and Upgrades

When selecting cable assemblies, consider future expansion and technological advancements. Opt for products that offer:

- Scalability: Solutions that can accommodate future growth and increased capacity.

- Compatibility: Make sure the cable assembly is compatible with new technologies and industry standards.

- Modularity: Modular designs allow for easy upgrades and reconfiguration.

Planning for the future minimizes the need for frequent replacements and upgrades, saving time and resources.

Focus on Environmental Sustainability

As sustainability becomes a global priority, many industries in Indonesia are adopting eco-friendly practices. Look for cable assemblies that align with these values:

- Eco-friendly materials: Choose assemblies made from recyclable or biodegradable materials.

- Energy efficiency: Opt for designs that reduce energy consumption.

- RoHS compliance: Ensure the absence of hazardous substances.

Supporting environmentally responsible manufacturers contributes to sustainable development and aligns with corporate social responsibility goals.

Test and Verify Performance

Before finalizing your purchase, conduct thorough testing and verification to ensure the cable assembly meets your expectations. Testing should include:

- Electrical performance: Verify voltage, current, and signal transmission capabilities.

- Mechanical strength: Assess the assembly’s ability to withstand physical stress and environmental conditions.

- Compliance: Confirm adherence to industry standards and certifications.

Rigorous testing minimizes the risk of failures and ensures optimal performance in real-world applications.

Selecting the right cable assembly Indonesia requires careful consideration of various factors, including technical specifications, quality, customization options, and manufacturer reputation. By following the tips outlined in this article, you can make informed decisions that enhance the performance and reliability of your systems.

Whether you are seeking standard or customized solutions, prioritize quality and value to achieve long-term success. Collaborating with manufacturers of the cable assembly Indonesia and planning for future expansion will further ensure that your cable assembly meets the evolving demands of your industry. With the right approach, you can optimize connectivity, efficiency, and sustainability in your projects.